News

- The Academy of Engineering releases the strategic path of carbon peak carbon neutralityOn March 31, at the 6th International Conference on Innovation and Emerging Industry Development co-sponsored by the Chinese Academy of Engineering, Shanghai Municipal People's Government and the Ministry of Industry and Information Technology, the Chinese Academy of Engineering released the results of the major consulting project "China's Carbon Peak Carbon neutral Strategy and Path". According to the report, China's carbon dioxide emissions are expected to peak around 2027, with the peak controlled at about 12.2 billion tons. The results were jointly completed by more than 40 academicians, more than 300 experts and dozens of units organized by the Chinese Academy of Engineering, focusing on industrial structure, energy, power, industry, construction, transportation, carbon removal and other aspects of China's strategy and path to achieve carbon peak carbon neutrality. Du Xiangwan, academician of the Chinese Academy of Engineering and deputy team leader of the project, introduced: "To achieve the two goals of reaching the peak of carbon neutrality, a series of technological progress must be achieved in various aspects of industry, transportation, construction, electricity and so on. China's existing technology is still not enough, and the path highlighted in this report is technological innovation." The report "China's Carbon Peak Carbon neutral Strategy and Path" completed by the project team points out that achieving carbon peak carbon neutral is the only way to promote high-quality economic and social development in China, but also faces many challenges. In order to orderly promote China's carbon peak carbon neutral work, we should focus on sticking to eight strategies. First, the strategy of giving priority to conservation, upholding the concept that energy conservation is the first energy, and constantly improving the energy efficiency of the whole society. The second is the energy security strategy, do a good job in fossil energy emergency, properly respond to the unstable supply of new energy, and prevent the risk of external dependence of oil and gas and key minerals. Third, non-fossil energy replacement strategy, on the basis of safe and reliable new energy gradually replace traditional energy, and constantly increase the proportion of non-fossil energy. The fourth is the re-electrification strategy, focusing on the replacement of electric energy and the development of electric raw fuel, and vigorously improving the level of electrification in key sectors. Fifth, the strategy of resource recycling, accelerating the upgrading and transformation of traditional industries and business process reengineering, and realizing multi-level recycling of resources. Sixth, the carbon sequestration strategy, adhere to the combination of ecological carbon absorption and artificial carbon use, enhance the carbon sequestration capacity of the ecosystem, and promote the research and development of carbon removal technology. Seventh, digital strategy, comprehensively promote digital carbon reduction and carbon management, and help green changes in production and life. Eighth, the international cooperation strategy, major countries to build a community with a shared future for mankind to take responsibility, more efforts to deepen international cooperation. On this basis, the report puts forward seven ways to achieve carbon peak carbon neutrality by improving the quality and efficiency of economic development, building a clean, low-carbon, safe and efficient energy system, and accelerating the construction of a new power system with new energy as the main body. In order to better solve the problems faced in the process of achieving carbon peak carbon neutrality, the report also puts forward three recommendations, one is to maintain strategic focus, do a good job of overall coordination, and adhere to the national "chess game" and orderly steps to promote the realization of carbon peak carbon neutrality under the premise of ensuring the orderly operation of the economy and society and the security of energy and resources supply. The second is to strengthen scientific and technological innovation to provide a strong driving force for achieving carbon peak carbon neutrality, especially the realization of carbon neutrality must be supported by major breakthroughs in key technologies. The third is to establish and improve the system and policy system to ensure that the carbon peak carbon neutral task measures are implemented, accelerate the establishment of the total carbon emission control system, accelerate the construction of an integrated planning, promotion and assessment mechanism for pollution reduction and carbon reduction, and constantly improve the capacity support and supervision system construction.

2024 01/15

- Villavicencio, Argentina 100% recyclable PET bottles without labelsAnn Arbor, Michigan-based Amcor Rigid Packaging (ARP) said it has partnered with consumer goods company Danone to launch 100 percent recyclable polyethylene terephthalate (PET) bottles for Argentina's Villavicencio Water brand. The new label free bottle is made from 100 percent recycled materials and has a 21 percent lower carbon footprint compared to the previous bottle. "As a long-term partner, we are pleased to support Danone's mission to make a positive impact on the environment and our health," said Juan Cazes, General Manager of ARP Argentina. "Over the past two years, we have worked closely together to produce bottles that fully represent the Villavicencio brand, while maintaining the same visual elements. We use the highest quality materials to help ensure the safety of the container and the consumer in the process, while the bottles we make, with the help of the consumer, become just another bottle once recycled." Swiss-based Amcor, which describes itself as a global leader in developing and producing responsible packaging for food, beverages, pharmaceuticals, medical, home and personal care and other products, said it has committed to making all of its packaging recyclable, reusable or compostable by 2025. "Partnering with Danone, a global food and beverage company committed to inspiring a healthier world through food, is a natural step," the company said. Villavicencio bottles can be recycled multiple times, "helping to support a more circular economy," ARP said. ARP says most of the brand's packaging is made of PET, which it says is "easily recycled through mechanical or chemical recycling in most markets, even if the container uses a label." ARP said that removing the labels, as in the new Villavicencio design, provides a greater opportunity to increase the yield of recycled PET resin. "As one of our flagship brands in Argentina, Villavicencio adheres to our philosophy of being closely connected to nature," said Pablo Colombo, Danone's Purchasing Director. "If the environment is healthy, so are we. So in addition to providing quality products to our customers, we must do the same for our planet. The alliance with Amcor allows us to take another step in our commitment to sustainability, creating a bottle with a lower carbon footprint in addition to being 100% recyclable."

2024 01/15

- Samsung launches sustainable phone and watch accessoriesSamsung has partnered with the industry's leading eco-conscious designer, Sean Wotherspoon, to launch its latest collection of stylish, limited-edition sustainable mobile accessories. The Samsung Galaxy x Sean Wotherspoon Sustainable Accessories collection, which goes on sale on April 22, includes three cases for the Galaxy S21 and three straps for the Galaxy Watch4 series, as well as a free watch face available for download in Google Play. The Samsung Galaxy x Sean Wotherspoon series, made from 100% recycled and biodegradable materials, is the second product in Samsung's sustainably sourced series, where Samsung will work with designers to create a stylish set of mobile accessories specifically for Galaxy products. Sean Wotherspoon said: "The case and band curated for Samsung will come in three matching styles - Orchid, Dawn and Rain. The strap is composed of environmentally friendly TPU material, non-toxic, has no DMF residue in the final product, is non-plasticized, and can be recycled at that time. The Galaxy S21 case is also made from 100% recycled TPU material, using materials that make it fully biodegradable and environmentally safe."

2024 01/15

- Lenovo is the first to introduce 95%PCR plastic on ThinkPad productsOn August 17, Lenovo officially held an innovation Open Day with the theme of "Opening New Imagination" at its global headquarters in Beijing. In this innovation Open Day, in addition to focusing on the display of more than 180 technological innovation results, Lenovo also demonstrated its specific application and practice of green design innovation. At present, the more common post-consumer recycling (PCR) plastics in the market, the proportion of recycled plastics used in the processing process is generally 30% to 50%, and most of the rest are newly produced plastics and additives, and if you want to further improve the proportion of recycled plastics, the performance of the material will become worse. In order to better contribute to environmental protection, Lenovo has set its sights on increasing the proportion of plastic recycling. Since 2017, Lenovo and SONY have spent three and a half years of development, done 250 sets of formula experiments, nearly 40 formula verification, and 12 batch tests, and finally applied SORPLAS™ environmentally friendly materials, which are more than 95% of raw materials are recycled plastics (PCR), to Lenovo's products. At the beginning of 2021, the 95% recycled ThinkPad 45W/65W power adapter has been successfully mass-produced, covering about 85% of ThinkPad products, and it has also been introduced in speakers and notebook structures. The Lenovo team is determined to continue to explore the possibility of applying a high proportion of recycled materials on ThinkPad batteries, and boldly challenge higher problems! After dozens of formula adjustments, more than 100 tests and verification, adjust the molding process, while meeting the extremely high requirements, and solve the problems of short shot, trapped gas, and insufficient filling, successfully opened a new era of 97% battery recovery ratio. In April 2022, Lenovo successfully mass-produced the industry's first 97%PCC battery on the ThinkPad, further driving the process of accelerating the application of high recycling ratio plastics in the laptop industry. Compared to the 25% to 30%PCC batteries commonly used in the industry, this eco-friendly and cutting-edge PCC 97% battery makes a significant contribution to Lenovo's ESG strategy - applied in 10 ThinkPad products, it can reduce the use of 80 tons of virgin plastic and 171 tons of CO₂ emissions in a year. It is understood that in the next few years, Lenovo will continue to promote the high proportion of PCR materials in ThinkPad products, key caps, high-power power adapters and housings more widely used.

2024 01/15

- The National Carbon Peak carbon neutral Standardization Group was establishedRecently, the National Standardization Management Committee issued a notice on the establishment of the National Carbon peak carbon neutral standardization group, and announced the group's leader, deputy leader, consultant and expert members of 43 people. It is understood that the leader of the National Carbon Da Feng carbon neutral standardization group is a member of the Standing Committee of the National People's Congress, vice chairman of the Environmental Management Committee, the former vice president of the Chinese Academy of Engineering and academician of the Chinese Academy of Engineering Zhao Xiangeng; There are 4 deputy leaders, respectively, Deputy Secretary of the Party Committee of Beijing University of Technology, President, academician of the Chinese Academy of Engineering Nie Zuoren; Yu Xinli, Director general and Researcher of China Standardization Association; Zhao Penggao, Deputy Director of the Department of Resource Conservation and Environmental Protection of the National Development and Reform Commission; Li Zhiping, vice president of China Standardization Institute. The consultants include Du Xiangwan, former vice president of the Chinese Academy of Engineering and academician of the Chinese Academy of Engineering. The experts include 34 people, including director of the special committee of the China Society of Technical Economics and researcher Ma Lincong. The notice is clear that the National Carbon Peak carbon neutralization Standardization Group is responsible for putting forward proposals for the construction of China's carbon peak carbon neutralization standard system, guiding the development of national standards (standard samples), the application and implementation of standards, the internationalization of standards, coordinating technical proposals for relevant standards, and providing support for the technical consistency of relevant standards (standard samples) for carbon peak carbon neutralization. The National Carbon Peaking Carbon neutral standardization group should explore and form an effective working mechanism and model in accordance with the relevant requirements of the "Guidelines for the Construction of the Standardization General Group", constantly sum up experience, strive to promote the implementation of relevant work, and give full play to the basic and leading role of standardization in achieving the goal of carbon peaking carbon neutrality.

2024 01/15

- Plastic recycling has become an industry imperativeIn the challenging financial year 2021-2022, the EREMA Group, an Austrian supplier of recycling equipment solutions, delivered a remarkable report card. Revenues increased by 17%, with sales of €295 million and the number of employees increased to 840. "Once again, we have achieved milestone growth with our technology!" "The current market environment remains challenging due to increased power, energy and logistics costs and supply chain disruptions," said Manfred Hackl, chief executive of Erema Group. At Erema's Ansfelden, Austria, facility, 220 extrusion pelleting machines were manufactured and delivered to customers around the world during the 2021-2022 financial year. If individual components and modules such as filtration systems and fresh and deodorant technology are counted, the number delivered can reach 320 units. In addition, there are 53 extruders from Erema's Italian subsidiary PLASMAC. In the 2021-2022 financial year, the recycled pellet capacity of the extrusion granulation system delivered by Erema is approximately 1.34 million tons per year. Large factories became the dominant trend Erema said the current market segment for post-consumer materials is a clear indication of the trend towards larger plants, both for PET recycling and polyolefin processing. For example, the first VACUREMA®Basic 2628 T machine with an annual capacity of 40,000 tons was recently commissioned at a customer site in Brazil. The factory has a 10-meter-long special geometric screw with a diameter of 280 mm and a weight of 3.5 tons. The screw was developed and manufactured by Erema's subsidiary, 3S. "The manufacturing of this large-scale recycling facility is another example of Erema's advanced innovation and the resulting synergies." "Manfred Hackell said. It is worth noting that the market demand for equipment of Erema's subsidiary UMAC is still strong. In addition to the impact of the general trend of plastic recycling, due to the tight trend of the procurement market, customers prefer to choose existing equipment and systems that can be delivered on short notice. At the same time, companies that previously had little contact with recycling are becoming more interested in the topic. They are also increasingly interested in the topic by businesses that have so far had little contact with recycling. Their needs for feasibility studies, consulting and engineering services, project management and turnkey projects are met by Irema's group company KEYCYCLE. KEYCYCLE has also obtained the patent and distribution rights from Cadel Deinking for an innovative ink removal technology, which is currently being further developed using the Erema Group's proprietary technology to form products that meet industry standards. During the fiscal year, Erima's plant was modernised and a PLASMAC equipment demonstration centre was expanded in Milan. All companies in the Group have expanded their production plants as well as their call centers to meet the growing market demand. With the construction of the new research and development center in Ansfelden, Erema is continuously optimizing its architecture to prepare for the plastics recycling market of the future. From niche to just-needed According to Erema, plastic recycling is rapidly evolving from a niche market to a demand market. This is both a challenge and an opportunity for the entire plastics industry. The plastics industry and brands are increasingly recognizing the positive role that plastics can play in accelerating the transition to a climate-neutral, resource-efficient and competitive economy through recycling technologies. "It's not just collective goodwill, it's inspiring more and more very specific initiatives like the Circular Plastics Alliance." This is why the circular economy remains at the top of the agenda at K 2022." Erema said that at the upcoming K2022 exhibition, it will showcase its innovative technologies and professional services on a shared stand for the first time.

2024 01/15

- Canada bans single-use plastic productsEnvironment Canada has issued regulations banning the use of single-use plastics in the country. Canada's Environment and Climate Change Minister Steven Guilbeault and Health Minister Jean-Yves Duclos have issued regulations banning single-use plastics, including checkout bags, cutlery, dining utensils made of or containing plastic that is difficult to recycle, ring carriers, stirring sticks and straws (with some exceptions). According to a press release from Environment Canada, the ban on the production and import of these single-use plastics will come into effect in December. The government will allow businesses time to transition and exhaust existing stocks of these single-use plastic products by December 2023. The ruling also bans the export of these six types of plastics until the end of 2025. Environment Canada says it expects the ban to eliminate more than 1.3 million metric tons of hard-to-recycle plastic and more than 22,000 metric tons of plastic pollution. "We made a commitment to Canadians that we would ban single-use plastics. Today, that's exactly what we did, "Guilbeault said. "By the end of this year, you won't be able to manufacture or import these harmful plastics." After that, businesses will start offering sustainable solutions that Canadians want, whether it's paper straws or reusable bags. With these new regulations, we are taking a historic leap forward in reducing plastic pollution and keeping our communities and the places we love clean." Some trade associations expressed concern about the ruling The Plastics Industry Association (Plastics) in Washington said it was disappointed by the ban. "The neglect of manufacturing jobs on both sides of the border is concerning," said Matt Seaholm, president and CEO of Plastics. "The lack of comprehensive economic analysis in implementing such sweeping regulations is truly frustrating." As a result of this action, plastics companies will have to lay off staff or close facilities altogether. "Our members never want to see their product end up where it doesn't belong. But while banning a product will certainly make it disappear, replacing it with alternatives that are likely to have a greater impact on the environment is completely counterproductive." Seaholm added that these regulations ignore opportunities to recycle single-use plastics. "Banning these products will increase costs for businesses and consumers in the United States and Canada, without doing anything to significantly reduce waste or waste." The Canadian Chemical Industry Association (CIAC), based in Ottawa, Ontario, also expressed disappointment with the ban. "Banning some single-use plastic products will not solve the overall problem of plastic pollution and post-consumer plastic management," CIAC said. "We are disappointed that safe, inert plastic materials that play such an important role in Canadians' lives are being banned when innovative technologies such as advanced recycling effectively manage them," said Elena Mantagaris, Vice President, Plastics Division, CIAC. "We need to invest in recycling infrastructure and innovation, including managing compostable infrastructure rather than bans, to harness the $8 billion worth of plastic that is currently sent to landfills and recycled in the economy." CIAC reported that it plans to work with the Canadian federal government to understand the scope of the ban's impact on businesses.

2024 01/15

- Basf launches the new PuriCycle® for plastic recyclingBasf introduces PuriCycle®, a new line of advanced, high-performance products for the purification of complex waste plastic pyrolysis feedstock. PuriCycle's portfolio includes novel catalysts and adsorbents that selectively remove or transform various impurities from pyrolytic oils and enable downstream processes for recycled plastic streams. PuriCycle's ingredients meet industry standards and enable users to benefit from efficient purification and refining solutions that increase the flexibility of the overall chemical recycling process for plastics. PuriCycle can purify pyrolysis oil, it is a kind of by obtained secondary raw material for chemical recycling of plastic waste, and at the beginning of the value chain is applied to the production of new plastic process. Purifying the pyrolytic oil obtained from waste plastics is one of the most demanding techniques in chemical plastics recycling. Impurities in pyrolytic oils include halogens, nitrogen, oxygen, and sulfur compounds, but also higher active ingredients like dienes, which complicate downstream applications and severely limit further processing in the production process of new materials. Dr. Detlef Ruff, Global Senior Vice President of Process Catalysts at BASF, said: "With our PuriCycle portfolio, we are in a very good position to recycle chemical plastics and enable recycling of plastics. PuriCycle's portfolio cleans challenging pyrolysis oil processes, enabling closed-loop recycling of plastics, minimizing waste, and ultimately opening up new raw materials for the chemical industry."

2024 01/15

- Faurecia's new eco-friendly seats use 85% recycled materialsRecently, Faurecia launched its latest eco-friendly seat. Through the application of modular and sustainable recyclable materials, the CO2 emissions of the entire chair can be reduced by 30%. It is understood that the covering material of the seat uses recycled materials with a recycling rate of 85%, which can reduce carbon emissions by 52% compared to traditional covering materials. Seat headrest padding also uses lightweight, recyclable materials. Based on the hybrid fiber concept, the foam has a recovery rate of up to 70% and a 56% reduction in carbon emissions. The seat is the latest solution in Faurecia's Earth Protection Seat innovation program. Officially launched in 2021, the project aims to fundamentally change the traditional production model, material use and design of the seating industry in order to reduce the carbon footprint of the entire seat life cycle, improve recyclability and support the circular economy. Faurecia says that technological innovation in car seating will follow four golden rules: 1, the use of sustainable materials (including natural materials, low-carbon materials), recyclable materials and recyclable materials. 2, optimize the use of materials, including reducing the use and loss of materials in the production process. 3, avoid the mixed use of diverse materials. 4, Optimize the design of components and the entire seat system, so that it is easy to assemble and disassemble, so as to comprehensively reduce the carbon footprint of the whole life cycle of the seat product, and is committed to bring many benefits to the vehicle manufacturer. It is expected that by 2030, under the premise of ensuring seat comfort and safety, Faurecia's new generation of full set of seats using new materials and new technologies will achieve 30% carbon dioxide emission reduction and 15% weight reduction compared with traditional seats.

2024 01/15

- Henkel unveils Sustainable Development Goals frameworkToday, Henkel publishes its Sustainability Report, which describes its achievements and progress in the field of sustainability in 2021, and announces the new "2030+ Sustainable Development Goal Framework." The report shows that in 2021, Henkel will implement a sustainable development strategy in its business development, reduce CO2 emissions through initiatives such as green electricity conversion in the production process, and make further progress in sustainable raw material procurement and sustainable finance. By the end of 2021, Henkel has reduced the CO2 footprint of its production processes by 50% and is 100% powered by renewable energy in 21 countries. Today, Henkel uses 68% of its electricity from renewable sources. The newly released Henkel "2030+ Sustainable Development Goals Framework" includes three aspects. Regenerating the planet: supporting science and innovation to transform businesses, products and raw materials for a circular economy and a zero-carbon future. The second is thriving communities: harnessing the collective power of businesses and brands to support equality, education and social well-being to help people live better lives. Third, be a trusted partner: drive performance and systems change with integrity through a values-based corporate culture, a deep understanding of science, and a passion for technology.

2024 01/15

- Honeywell's plastic chemical recyclingHoneywell has partnered with a number of energy companies and plastic recycling companies to establish recycling plants that use the UpCycle process technology to convert waste plastics into recycled polymer raw materials. Chemical recycling is a process in which waste plastics undergo a series of chemical transformations to regenerate new plastics of the same quality as petroleum-based plastics, also known as "advanced cycle" and "molecular cycle", which are complementary to physical recycling. Of the nearly 370 million tons of plastic produced globally each year, less than 10% can be recycled. In recent years, due to the world's multinational policies and the international mainstream petrochemical, brand and packaging giant enterprises to invest heavily and other factors, the chemical recycling of waste plastics has become a hot topic of global concern. 1. On November 3, 2021, Honeywell announced the successful commercialization of a disruptive plastic recycling process. Honeywell's UpCycle process technology uses industry-leading molecular transformation, pyrolysis and contaminant management technologies to convert waste plastics into recycled polymer feedstock that can then be used to make new plastics. The UpCycle process technology significantly broadens the range of plastics that can be recycled, including waste plastics that would otherwise not be recycled, coloured, flexible, multilayer packaging or polystyrene. When combined with other chemical and mechanical recycling processes and improvements in collection and sorting, UpCycle technology is expected to increase the proportion of plastic waste that can be recycled globally to 90 percent. 2. In November 2021, Honeywell and Sacyr announced a joint venture in Andalusia, Spain, to build and operate a plant capable of processing 30,000 metric tons of mixed waste plastics per year, with production expected to begin in 2023. The plant will use Honeywell's chemical recycling UpCycle process technology to convert waste into recycled polymer feedstock, or RPF. Honeywell has already entered into strategic agreements with Total Energy and French chemical company TotalEnergies. Honeywell will provide RPF for Total Energy, TotalEnergies, which will source the feedstock and convert it into high-quality polymers suitable for high-specification applications such as food-grade packaging. 3. On February 17, 2022, Honeywell announced that it will form a joint venture with Avangard Innovative, the largest plastics recycling industry leader in the United States, to build an advanced recycling plant in Texas, USA. The new plant, which will use UpCycle process technology, is expected to be operational in 2023 and will convert 30,000 metric tons of mixed waste plastic per year into Honeywell recycled polymer feedstock.

2024 01/15

- SABIC launches lightweight PP for foldable logistics turnover boxSaudi Basic Industries Corporation (SABIC), in partnership with logistics recycling packaging innovator Cabka, has launched a new generation of foldable logistics turnover boxes, the CabCube4840. In less than six months, the two companies collaborated to develop several high-performance polypropylene compounds. These composite solutions improve the processing performance of the logistics box, increase its strength and impact, and reduce its weight. Some of these materials are unique grades in SABIC's portfolio of foam and lightweight products, which are flame retardant, halogen-free and UL94-V0 certified. The two companies are also collaborating on solutions for polyolefin compounds containing mechanically recycled components. The two companies said they hope to improve SABIC's logistics packaging system through the partnership, starting with SABIC's composite plant in Belgium, where "one-way" wooden pallets and cardboard boxes are replaced with lightweight, recyclable plastic packaging. "SABIC offers more than 20 innovative foam and lightweight solutions that enable customers and partners across the value chain to overcome the challenges they face and meet consumer demand for smarter, more sustainable solutions." Abdullah Al Otaibi, General Manager, ETP& Market Solutions, SABIC. Jean-marc vanMaren, Chief Product Officer at Cabka, added: "The Cabka is available in a variety of CabCube designs, sizes and specifications, which create significant efficiencies for customers in the supply chain. With SABIC's support, our sustainable logistics bins are more reliable and secure than existing solutions on the market."

2024 01/15

- Pirelli launches a new logo for sustainable tyresTo make it easier for consumers to find more sustainable tires. Pirelli has created a custom logo for its tires that contains at least 50% bio-based and recycled materials. The new logo has two circular arrows that will be adopted on new products. The latest tag was first used on P Zero E. The tyres contain over 55% bio-based and recycled materials and are certified by Bureau Veritas. Pirelli said that all future products with the new logo will continue to adopt third-party verification standards for ecologically compatible materials. The main challenge in developing the new P Zero E was to combine the need for sustainability with the high performance required for ultra-high pressure tires. Pirelli said this goal was achieved thanks to new materials. These include lignin from pulp and paper industry waste, rice husk ash silica from waste rice farming, and recycled carbon black. Biocyclic polymers derived from used cooking oil and tire pyrolysis oil are also used, as are bioresins, rayon and, of course, natural rubber. Giovanni Tronchetti Provera, Head of Sustainability and Future Mobility at Pirelli, said: "For several years now, Pirelli has been reducing its environmental impact and this policy is confirmed by all the major sustainability indices, which recognise our commitment and transparency in terms of results and spirit. For this reason, we use 'at least' rather than 'at most' to represent the percentage of sustainable materials. We will now continue on this path with the recognition and appreciation of our automaker partners." Pirelli's approach to reducing its environmental impact includes increasing the use of sustainable materials. Its target, originally set for 2025, has been met, thanks to P Zero E. The next step, a target set for selected product lines by 2030, envisages the use of at least 60 percent bio-derived materials and 12 percent recycled materials, with less than 30 percent fossil-derived components. With an increasing proportion of sustainable materials, these innovations open a path on a quantitative level, but also on a quality level by certifying supply chains to meet internationally recognized standards.

2024 01/15

- Industrial application of carbon reduction PCR materialsUnder the severe conditions of energy shortage and climate change, PCR has caught fire, and many end users have been at the forefront of "carbon reduction" under the trend of "carbon reduction", reducing the carbon content of their products from the source of materials. Automobile industry According to the data on the official website of the Passenger Car Market Information Association, starting from 2021, the sales proportion of new energy vehicles has increased, which indicates that the proportion of the automotive industry market is tilted to the field of sustainable development under the guidance of various policies. Some automotive Oems are active, such as Volkswagen's commitment to become carbon neutral/green and zero emissions by 2050. Renault has pledged to reduce its CO2 emissions by 50% from 2010 levels and to become carbon neutral by 2050. Compared to cars, the total greenhouse gas emissions of electric vehicles over the life cycle of the vehicle are only half that of fuel vehicles. Home Appliance industry The home appliance industry has many products made of carbon-reducing materials. By recycling consumer electronics such as used hair dryers and vacuum cleaner parts, Electrolux has developed a vacuum cleaner made from 100% recycled and reused materials in 2020. For example, Google's new smart home products have a high content of recycled materials, including the Nest thermostat and smart speaker containing 75% and 70% recycled plastic, respectively. European white goods brand Beko practices harmony between people and nature, developing a series of home appliances, these products have about 15% of plastic parts from waste plastic. OA industry Not only the home appliance industry, OA industry also has a lot of mature products. For example, Microsoft's "carbon reduction" extends from the product itself to the packaging of the product, and the environmentally friendly wireless mouse they produce has 20% of the shell using Marine recycled plastic, and the packaging box is made of 100% recycled materials. In addition, 40% of Konica Minolta's printer housing comes from Kumho Ilri Ecoblend® PCR plastic. Coincidentally, Lenovo's new AIO520 desktop computer shell in 2021 also uses PCR plastic, it is worth mentioning that the shell material used in this desktop computer is both PCR plastic and plastic Cori ® aesthetic plastic. The plastic is injection molded once, which reduces carbon emissions during processing and is easy to recycle again.

2024 01/15

- KIA will use 55 tons of Marine plastic in its electric carsKIA plans to use 55 tons of recycled Marine plastic recently recovered from the Pacific Ocean in its new electric models. The record-breaking amount of plastic recycled by Kia's global partner, The Ocean Cleanup, marks the next phase of a seven-year global partnership agreed in April 2022 as part of Kia's transformation into a leading provider of sustainable mobility solutions. System 002 extraction technology The Ocean Cleanup, an international non-profit project whose mission is to rid the ocean of plastic, captured plastic in Victoria, Vancouver Island, Canada. After a long voyage through the Great Pacific Garbage Patch (GPGP), a record catch was removed from the Pacific Ocean using the Ocean Cleanup's System 002 extraction technology. The GPGP is the largest floating garbage dump in the world, with an estimated surface area of 1.6 million square kilometers, equivalent to three times the size of France. The recycling of the recycled plastic will begin soon, and Kia will use some of the material in future models. The policy is in line with Kia's commitment to provide sustainable mobility solutions that have a measurable impact on achieving sustainability at scale. Sustainable solutions implemented by KIA KIA has successfully implemented more than 30 sustainable solutions in various product areas, including the use of recycled PET, bio-based alternative leather and fabrics and carpets free of BTX paint. In the case of the brand's flagship EV9, a seven-seater all-electric SUV, recycled waste, including fishing nets recovered from the ocean, is used to create the vehicle's floor carpet. The EV9 is constructed using components made of recycled plastic and bio-based environmentally friendly materials and weighs about 34 kg. Immediately after bringing a record catch to shore, the Ocean Cleanup announced the launch of its new System 03 technology. With nearly three times the volume of System 002, System 03 can capture a greater amount of Marine plastic continuously throughout the year at a lower cost per kilogram of removal. It also features more advanced environmental monitoring and safety technologies, such as a new Marine animal safety hatch designed to protect Marine life. The expansion marks the next stage in the Ocean Cleanup's goal to remove 90 percent of floating ocean plastic by 2040.

2024 01/15

- Walkers launches new packaging made of 50 per cent recycled plasticWalkers has announced a transformation of its Sunbites line with the launch of new packaging made from recycled plastic, and the entire line is now classified as non-HFSS. The new packaging is made from 50% recycled plastic and sourced using a mass-balanced approach, which means buying and using enough mass-balanced recycled plastic material to eliminate 200 tons of fossil-based plastic from Sunbites packaging by the end of 2025. It is the latest in a series of packaging innovations by Walkers, with the brand recently launching new paper outer packaging for its entire Walkers Baked collection and a cardboard design for Walkers 20-bag multi-piece packs. The release is part of PepsiCo's Positive (pep+), Walkers parent company's health and sustainability plan, which includes an ambition to eliminate native fossil-based plastics from crisps and snack bags in Europe by 2030. Sunbites joins Walkers' line-up of non-HFSS favourites including 45% Less Salt, Baked, Doritos Dippers and PopWorks, solidifying the brand's leadership in developing healthier, tastier snacks for people across the UK. Last year, Walkers set a goal that snacks that are not HFSS or sold in portions of less than 100 calories would account for 50 percent of its sales by 2025. Eighteen months later, Walkers is more than halfway to that goal, with 30 percent of the snack brand's sales coming from healthier snacks. Gareth Callan, UK Head of Sustainable Packaging at PepsiCo, said: "Sunbites' transformation is a sign of our continued commitment to delivering products that are better for people and the planet. We are proud of the progress we have made so far in reducing the fossil-based plastics we use and meeting the growing demand for healthier snack options, without sacrificing taste." We are working on reinventing our packaging. To help us do this at scale, we urge the UK government to recognise the role that chemical recycling and other emerging mechanical technologies can play in creating demand for food-contact soft plastics - including amending the plastic packaging levy to stimulate a circular economy for UK packaging." As PepsiCo works to achieve these ambitious targets, it sees the expansion of food contact recycling technologies, such as chemical recycling, and associated recycling infrastructure playing a key role in developing capabilities to meet growing demand, while supporting a circular economy of packaging used in the UK food manufacturing industry.

2024 01/15

- APR Expands APR Design Recognition Program for Plastic RecyclingThe Plastics Recycling Association (APR) recently announced that six new packaging components are eligible for its Preferred Design Approval (PDR) program, previously known as Compliance with Preferred Guidelines (MPG). The APR Design Accreditation Program ensures that products are compatible with North American recycling systems through third-party verification and receive preferred status according to APR's Plastic Recyclability Design Guidelines, the organization said. New packaging components to the APR Design Recognition Program include: ◆ Polypropylene (PP) base resin; ◆ Suitable for direct printing of PP packaging; ◆PP container lid, accessories and lining; ◆ Complete and unprinted label structure suitable for PP packaging; ◆PP containers, bottles and rigid packaging; ◆ and PP packaging structure. APR said the program will be further expanded to include categories of polyethylene terephthalate (PET) and colored high density polyethylene (HDPE) containers and packaging structures, as well as natural HDPE packaging and PE films. A full list of current and upcoming categories can be found here. "Since its inception more than 20 years ago, the APR Design Recognition Program has reviewed and endorsed packaging from more than 120 companies, driving mainstream adoption of impactive innovations in plastic packaging, increasing its recyclability and reducing the generation of plastic waste," said Ruben Nance, Director of APR's Preferred Design Recognition Program. "The expansion of APR's Preferred Design Recognition program will save brands and retailers the time, effort and resources needed to identify recyclable packaging solutions." Depending on the type of plastic submitted, the APR Design Recognition Program has three paths: Preferred Design, Critical Guidance, and Responsible Innovation. All paths eventually reach the same level of approval, meaning that the product meets the highest recyclability standards according to the APR design guidelines. For component and packaging manufacturers, APR says the APR Design Recognition program rewards the investment needed to solve recycling challenges and replace problematic items. For brands and retailers, the organization added that the program provides confidence and reduces risk when making claims and complying with voluntary or legislative sustainable packaging requirements. The program also aims to help increase the supply of post-consumer recycled ingredients (PCR).

2024 01/15

- PCR Recycled Material To Be Used To Promote An Environmentally LifestyleDubai has banned the use of single-use plastic bags since January 1, 2024. The decision, which came into effect by Sheikh Hamdan bin Mohammed, Crown Prince of Dubai, aims to promote an environmentally friendly lifestyle, encourage businesses to use recycled products and promote a sustainable local recycling and recycling circular economy. It is understood that the resolution applies to single-use and recycled products, including plastic and non-plastic products, covering food delivery packaging materials, fruit and vegetable packaging, thick plastic bags, plastic bottles, snack bags, wipes, balloons and balloon sticks. The plastic restriction order will be promoted in stages: ◆ From January 1, 2024: Applicable to disposable plastic bags. ◆ From June 1, 2024: non-plastic disposable products will be included in the scope of the ban. ◆ From January 1, 2025: Single-use plastic products, including plastic mixers, table sets, cups, styrofoam food containers, plastic straws and plastic cotton swabs will also be banned. ◆ From January 1, 2026: It will be expanded to other disposable plastic products, including plastic plates, plastic food containers, plastic tableware, beverage cups and their plastic LIDS. Films used for food packaging are not included in the prohibited scope The plastic limit today pointed out that will be used to carry meat, fish, vegetables, fruits, public property, bread and garbage bags will not be included in the scope of disposable plastic bags. In addition, plastic bags made from recycled materials and plastic products exported to foreign countries are not included in the prohibited products. If companies continue to use single-use plastic bags, they will be fined 200 dirhams (about 388 yuan), and the fine will be doubled for each violation within 12 months, up to 3,883 dirhams. Recycle PET plastic bottles to make cleaning clothes Notably, the Dubai Government has also launched the "Net Zero Emissions by 2050" initiative to encourage the government and private sector to improve waste management, increase the proportion and quality of recycled materials, and promote sustainable development, circular economy and waste recycling. For example, the Dubai government has worked with the company "DGRADE" to convert plastic bottle recycling into cleaners' work clothing. It is understood that the project by recycling 3 million plastic bottles (about 60 tons of PET) to produce work clothing for municipal employees. Dubai will become the first municipality in the world to use recycled materials to produce valuable products for its employees. Set up 100 smart recycling devices for plastic packaging The Dubai Municipal Government has also placed 100 smart plastic packaging recycling machines in government offices and private enterprises, as well as sports venues, and designated 17 recyclable material collection centers for public use in densely populated areas. The Dubai government said that through smart recycling equipment and recycling centers, more members of the public can participate in the recycling of plastics. "These measures underline Dubai's commitment to reducing the impact of waste, promoting recycling and supporting a green, circular economy." Summed up by Dawud Al Hajri, Director-General of the City of Dubai.

2024 01/15

- 3D Printing For Plastic Prototype Parts3D printing is a revolutionary technology that creates three-dimensional products by adding material layer by layer to the device, and these materials form its most critical material basis. The continuous innovation and progress of materials plays a crucial role in whether 3D printing technology can be applied in a wider range of fields. At present, China's 3D printing is mainly concentrated in engineering plastics, resins and some common metal materials. However, it is worth noting that in terms of raw materials, domestic production enterprises are relatively few, especially in terms of metal materials, and still rely on imports. Therefore, in order to promote the development and application of 3D printing technology, we need to increase investment in the research and development of 3D printing materials and cultivate more domestic production enterprises. Especially in terms of metal materials, it is necessary to strengthen scientific research cooperation, promote the independent production capacity of domestic metal 3D printing materials, and reduce dependence on imports. This can not only improve the competitiveness of China's 3D printing industry, but also promote its application in a wider range of fields, and promote the upgrading and transformation of the manufacturing industry. In the future, China is expected to play a more important role in the field of 3D printing technology and become one of the world's leading innovation centers. Engineering plastics are one of the most widely used materials in commercial 3D printing today, favored for their outstanding characteristics such as impact resistance, heat resistance and aging resistance. In application, engineering plastics can not only be used for the manufacture of mechanical structures and components, such as fixtures, brackets, etc., but also for the manufacture of automotive parts such as interior parts and body parts. Photosensitive resin is a kind of material with the characteristics of fast curing rate, high temperature resistance and light sensitivity, which will undergo photochemical reaction under ultraviolet light, so as to cure and harden quickly, which is suitable for making high-precision parts. Because the photosensitive resin is controlled by the precise beam when curing, it can achieve very high printing accuracy and detail performance, which is suitable for the production of complex geometric shapes and delicate surfaces, so the photosensitive resin is often used in the printing of medical devices, jewelry, etc. The application of synthetic rubber in 3D printing is relatively new, but with the continuous progress of technology, it is gradually showing broad application prospects, it is a rubber material made of chemical synthesis, with excellent elasticity and wear resistance. Because of its excellent elasticity, synthetic rubber is often used to make springs, seals, shock absorbers, etc., and can also be used to make flexible shells and packaging to protect fragile products.

2023 11/18

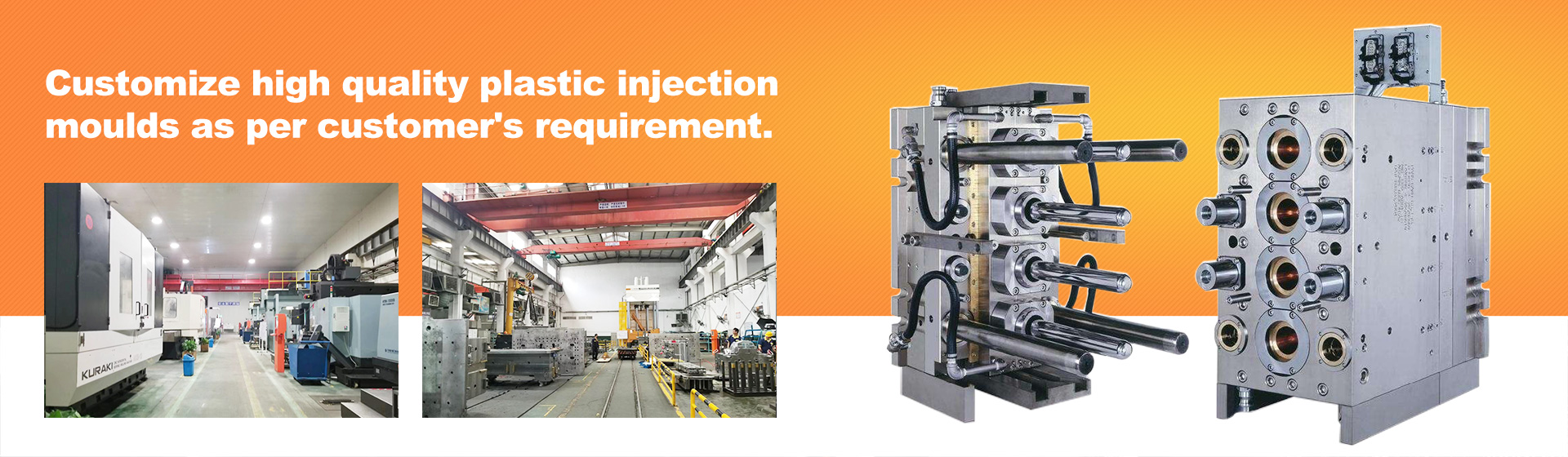

- Plastic Injection Mold Cooling Lines DesignIn injection molds design field, commonly used types of water lines or cooling lines are mainly referring the following: 1. Linear waterway: linear waterway channel, simple and practical, suitable for plastic products with small size injection molding. 2. Circular waterway: compared with linear waterway, the flow resistance of circular waterway is smaller, but it is not suitable for injection molding with larger product size. 3. Snail type waterway: The waterway is snail shaped, which can effectively improve the filling performance of plastic products, but the processing difficulty and cost are correspondingly high. 4. Plunger type waterway: the waterway with the plunger as the core can ensure that the product is filled, especially suitable for processing large closed products. 5. Soaking water: The use of special soaking water and efficient circulation water, can effectively improve the quality of injection products, but the cost of equipment and materials is relatively high. Two, injection mold water design principles In the process of injection mold water design, the following principles need to be followed: 1. The water is as short as possible to reduce cooling time and improve production efficiency. 2. The waterway is as large as possible to increase flow and reduce flow resistance. 3. Water should be evenly distributed to ensure that plastic products are filled evenly. 4. The water should avoid direct contact with the wall of the mold cavity to avoid uneven cooling. 5. The waterway should avoid bending and dead corners, so as not to collect water and foam. Third, injection mold water processing method The main processing methods of injection mold waterways are as follows: 1. Drilling method: directly on the mold drilling molding, simple operation, but difficult to control the aperture and position accuracy. 2. Copper tube method: The copper tube is embedded on the mold, the pipe diameter and position accuracy is high, but the processing is complicated and the cost is correspondingly high. 3. Welding method: The use of electron beam welding or laser welding technology to accurately weld the components of the waterway on the mold. Four, injection mold waterway common failure In the process of injection mold production, common water faults include the following: 1. Too high or too low water pressure: it may affect the filling performance and dimensional accuracy of plastic products. 2. Water blockage: may lead to the surface of plastic products is not smooth, blisters and other defects. 3. Water leakage: it may affect the production efficiency of injection molds and the quality stability of products. Taking the above points into account, injection mold waterways play a crucial role in the injection molding production process. Proper waterway design and processing can effectively improve the quality and production efficiency of plastic products and reduce production costs.

2023 11/18

Email to this supplier